SYSTEMS

AutoLaner Laning and Balancing

An automated laning and balancing system that divides a randomly distributed product stream equally into multiple channels or lanes.

The AutoLaner is a series of controlled lanes that automatically divides a randomly distributed product stream equally into multiple lanes (typically 4 or 6).

Multi-lane, Multi-aperture System Boosts Efficiency and Reduces Cost of Ownership

Typically slicing and/or packaging equipment requires product to be laned at its input, and that each of those lanes are filled equally. Often this task is completed with manual labor. An AutoLaner takes randomly placed product and automatically lanes and meters product as it enters packaging; ensuring constant monitored and regulated product flow.

The AutoLaner logic is prepared to deal with surges of product and when packaging equipment is temporarily unavailable.

AutoLaner Laning and Balancing System

Standard system configurations are for 4 and 6 lanes, but can be varied further in software as required for each SKU produced. The system can handle over 150 pieces per minute, per lane.

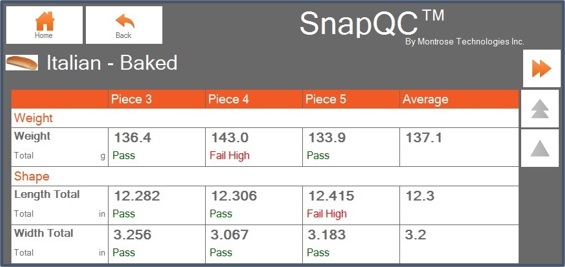

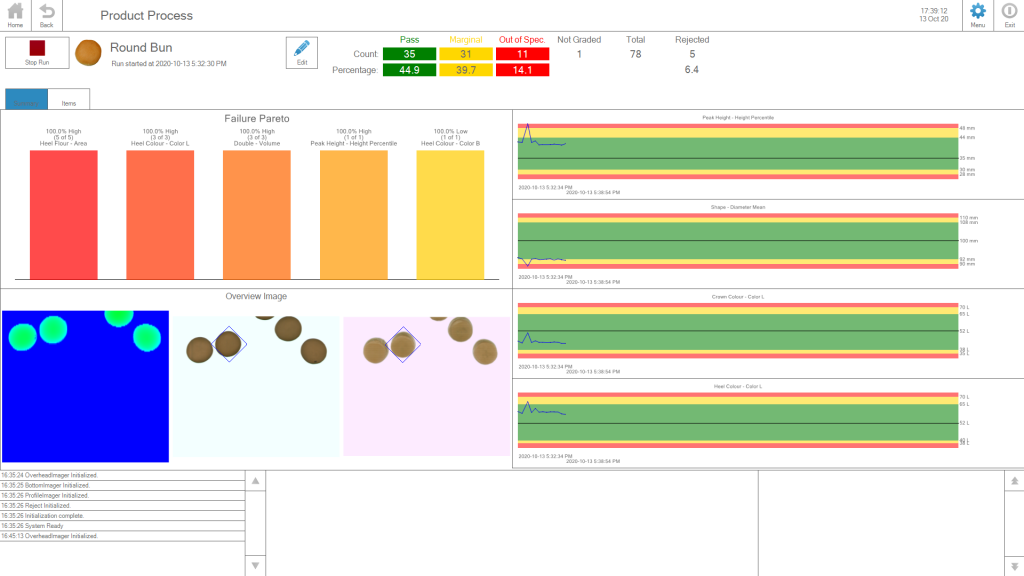

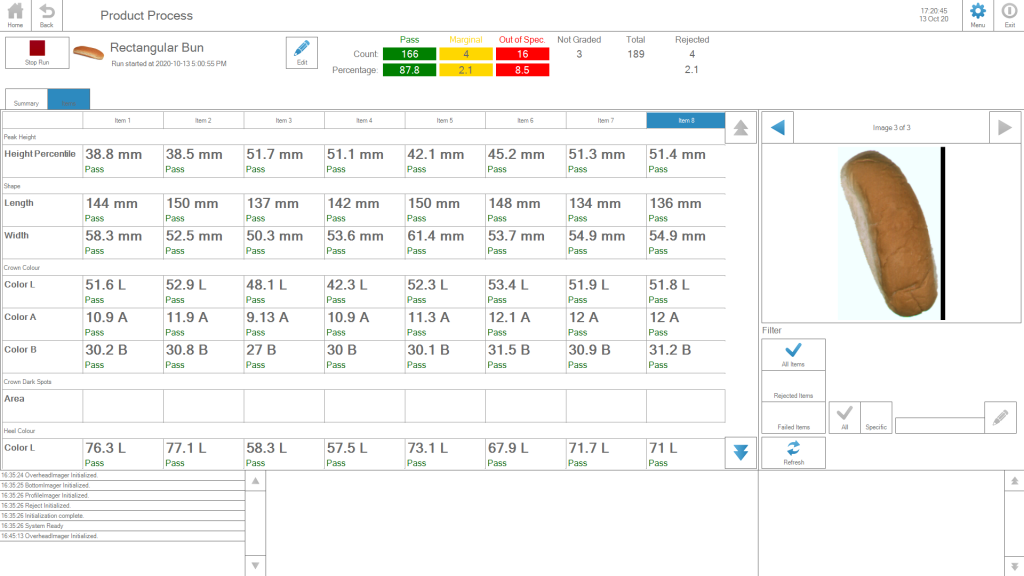

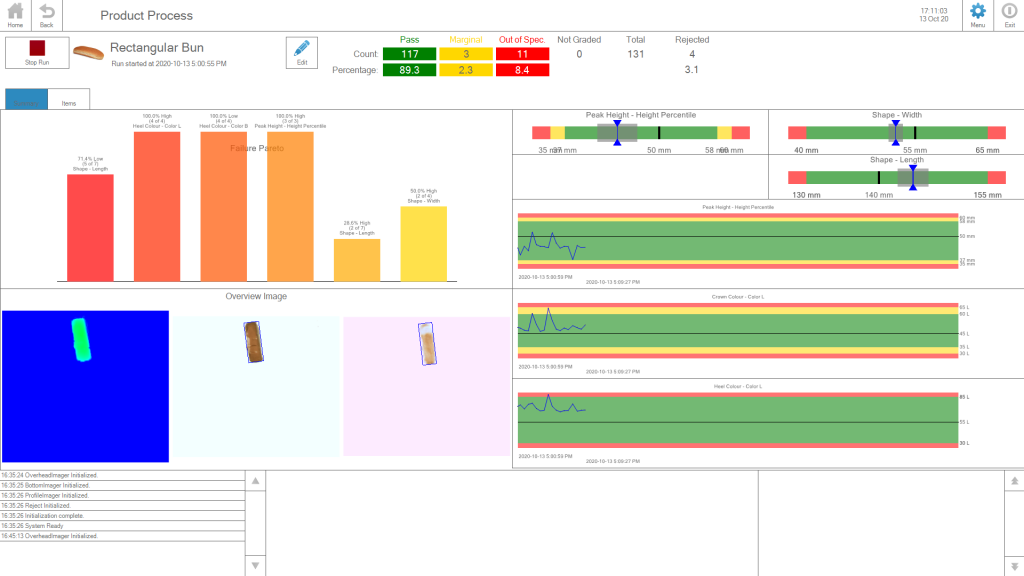

Montrose Inspection Software

Montrose Technologies provides fast, accurate information to help you make money-saving decisions on product quality, wastage and production rates. The Inspection Software is a comprehensive suite of measurement, analysis, reporting and archiving functions designed to meet the needs of plant floor operators as well as plant managers. On the plant floor, the software displays shape, size, dimensional, color and external data in a variety of graphical and numerical formats. Operators have fast and easy access to current results.

Key Benefits:

- Simple operator interface (touchscreen-driven)

- Results displayed in numerical and statistical format

- Full data storage for averaged and individual object measurements

- Interfaces to external devices such as a barcode reader

- Can export raw data to other software packages (e.g. ERP)

- Supports unlimited lines and products

- Simple to setup, calibrate and operate

- Includes measurement data report generation

Improve quality, reduce production costs, provide valuable data.